Casting the future

Made from Metal Powder with experience & Skillful Craftman to meet the unique requirement

We believe that the finished quality of iron casting is largely determined by the quality of the pattern from which designed drawn.

That's why we insist on manufacturing our own patterns in house, leveraging precise CAD models to produce CNC machined patterns.

- Engineering Services and Consulting

- Aluminum Patterns

- Prototype

- Casting Simulation Process

- Maintenance and tooling

Our in-house pattern workshop, outfitted with high-performance CAD and precision CNC machining center for rapid prototyping; allows for seamless integration between design and production, enhancing efficiency and quality control.Cinacasting has consistently improving in custom pattern-making and embracing cutting-edge solutions.

If you possess existing patterns, cores, or tooling, our array of production equipment enables you to transition your casting process to the optimal molding line that aligns with your work.We will evaluate your tooling when we receive it and work with you to ensure the most cost-effective solution.

Melting

State-of-art efficient production is assured by our metallurgical process:24tons electric-melt system,highly efficient from an energy and environmental point of view, with low emissions that contain no NOx, SOx, CO or dioxins and produces a reduced amount of dust, CO2 and waste.

most cost-effective for creating a wide range of products from small & simple to large & complex , ideal for the prototyping and early bulk production.

can produce highly complex parts through sand casting molds from multiple pieces and create objects with holes, undercuts, protrusions and internal channels.

usually extremely accurate and can reliably produce objects to precise specifications.

typically low cost on tooling; relatively short process, patterns can be repeated usage, and modifications to tools usually are relatively simple, all brings down costs.

The lead time is relatively short,whatever for making molds or tooling,especially useful for short production runs.

easy to recycle through many production cycles; more environmentally friendly and helps reduce costs.

Core-Making

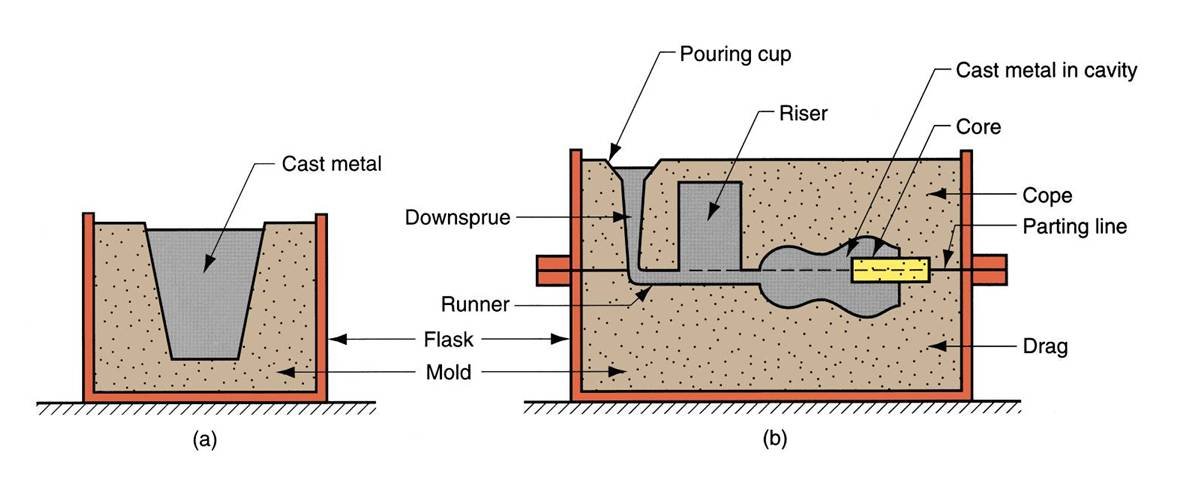

Cores are used to provide cavities within a casting;an expendable & flexibility casting that uses a resin covered sand to form the mold;is produced using a metal pattern, heat and a sand-resin mixture.

Molding in Green Sand Foundry with two automatic molding lines, one horizontal (530×610) and one vertical (600×800), with a maximum individual casting weight of up to 100 kgs.

cinacasting is proud to produce precision iron casting eco-friendly through the green sand casting process;utilizing sand as the primary material without any other additives besides clay and water. The moisture content within the mold itself provides the necessary binding structure for the sand.cinacasting recycles sand,thereby minimizing waste and reducing the environmental impact of our manufacturing processes; delivering products that meet both stringent quality standards and environmental considerations.

CASTING

Expert Prototype Manufacturing With Advanced CAD Modeling Services

At cinacasting, we believe that the quality of a casting is determined by the pattern from the designed drawing. We take pride in delivering the quality patterns and casting services possible.

Maintaining the entire process within our facilities allows us to control quality, protect timelines, and ensure cost certainty while producing patterns that deliver superior casting performance.

When focusing on speed and proof-of-concept, our engineering team operates directly within SOLIDWORKS and validates each design using solidification modeling for Solidification Time, Pouring Temperature, Fraction Liquid, and FeedMod, prior to the pouring of any iron.

Once simulations are approved, we machine the tooling in-house and generate production-ready toolpaths, providing you with dimensionally accurate prototypes, thereby reducing errors and outsourcing delays.

Our straight-line workflow, beginning with digital simulation and pattern building, then molding and metal pouring, all through In-house Fully-integrated production system. Should you require machining for your castings, we are equipped to handle that as well. The iron castings we produce are poured in two automatic molding lines, one horizontal (530×610) and one vertical (600×800), with a maximum individual casting weight of up to 100 kgs. Cinacasting can assist with daily production capacity up to 25tons, producing every iron grade, including HT350 and QT800. Need for little stronger? We can also provide specific customization for iron grades.

We desire to be Preferred Global Partner for YOUR FOUNDRY, not only manufacturering what you need, but also committing to offer whole chain service. Made with our experiences and expertise based on thousands of moulds and tooling ; whatever only give us a drawing only, whatever you need elctropheries or dipping paint, whichever products or design; the operability is reliable from us to you.